Your cart is empty.

- +989365257488

- info@tomexa.com

- Head office: United Arab Emirates

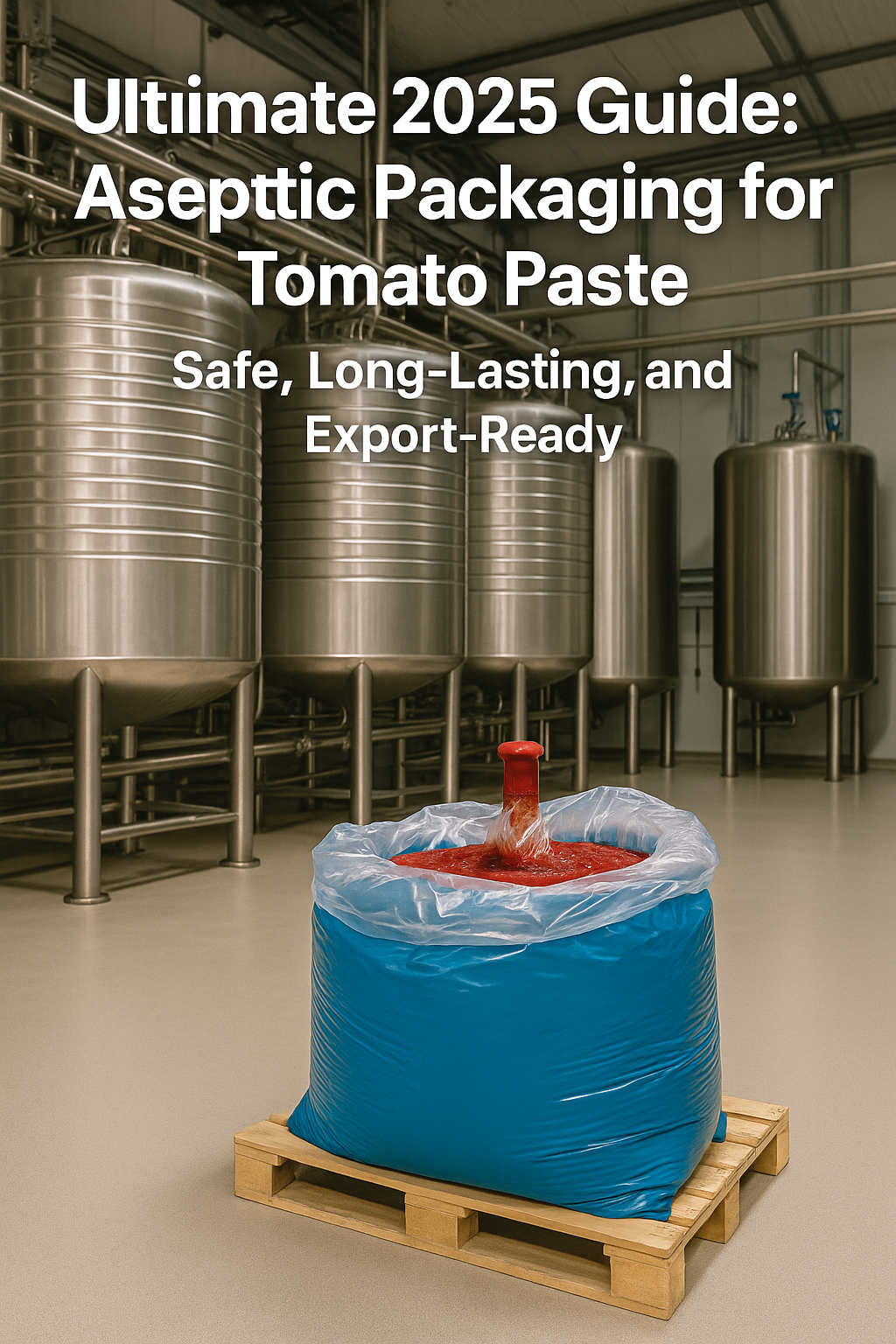

The aseptic packaging for tomato paste is revolutionizing global food exports. It ensures long shelf life, product safety, and compliance with international standards — all without preservatives.

In this guide, we’ll explain how the process works, why it matters for importers, and what sets it apart from traditional packaging methods.

Aseptic packaging for tomato paste involves sterilizing the paste and packaging separately, then filling the product into sterile containers in a controlled environment. This allows for 18–24 months of storage at room temperature without spoilage.

Aseptic packaging is essential for international shipping, especially in regions like Europe and Africa. It eliminates microbial contamination and complies with the strictest import regulations.

Aseptic tomato paste is typically packed in 220–240 kg drums or in 24-ton flexi tanks for bulk export.

| Step | Description |

|---|---|

| 1. Product Sterilization | Tomato paste is heat-treated at 90–110°C to destroy bacteria. |

| 2. Packaging Sterilization | Steel drums or bags are steam or chemically sterilized. |

| 3. Aseptic Filling | Product is filled into drums using closed-loop aseptic machines. |

| 4. Sealing | Filled drums are sealed under sterile airflow. |

| 5. Storage | Drums are stored at room temperature for up to 2 years. |

Every batch undergoes lab testing for:

Tomexa ensures full traceability and compliance with ISO 22000, HACCP, and FDA standards.

Aseptic systems meet the requirements of:

The aseptic packaging for tomato paste is the gold standard in global trade. Whether you’re an importer or distributor, choosing aseptic ensures reliability and peace of mind.

👉 Contact Tomexa today to receive a customized quote and documentation.

Subscribe to our newsletter and receive the latest updates on aseptic tomato paste and fruit juice concentrates, new products, and export offers.